Diamond-Like Carbon Coating (DLC) is the ultimate performance coating, offering a wear-resistant chemical barrier for metal, ceramic, glass, and plastic, normally deposited at temperatures below 150°C.

DLC is ultra resistant to abrasive and adhesive wear, rendering it suitable for use in both rolling and sliding applications that experience extreme contact pressure. Unlike graphite, DLC provides high lubricity at both ambient atmosphere and at vacuum.

We offer three specialized DLC processes: Advanced Auto Pro (AAP), Advanced Mold Pro (AMP) and Advanced Combo Pro (ACP).

DLC films are amorphous and consist of a mixture of sp2 (graphite) & sp3 (diamond) phases. The film properties are strongly dependent on the flux characteristics of the chosen deposition process (PVD sputter or evaporation and PACVD), metal and hydrogen content within the film, sp2:sp3 ratio, substrate bias voltage, ion energy and density, as well as substrate temperatures.

Crystallinity | Amorphorous |

Micro-hardness | 20 – 30 GPa |

Coefficient of Friction Against Steel (dry) | 0.05 – 0.1 |

Coating Thickness | 1 – 2 µ |

Maximum Working Temperature | 300°C (570F) |

Maximum Coating Temperature | |

Thermal Conductivity | 100 – 150 (W/(m·K)) |

Coating Method | PACVD |

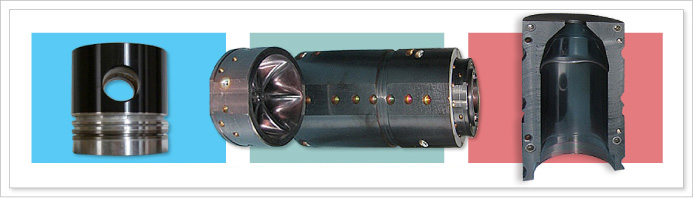

A DLC process which helps automotive designers achieve the EU6 emission limit and ensures component reliability with a surface solution that combines reduced friction and excellent wear protection.

Designed for highly stressed components, AAP is characterized by its extremely smooth surface and self-lubricating properties. Even in low lubrication conditions, the coating decreased the coefficient of friction significantly, performing as well as in well-lubricated conditions.

This Plasma-Assisted Chemical Vapour Deposition (PACVD) process activates chemical reactions through plasma excitation and ionization. It has been designed with the engineering, automotive, plastics processing, and semiconductor industries in mind. To guarantee best quality and performance, AMP coating is applied in a clean environment at a temperature range of 180°C – 220°C.

This process is deposited by a combination of PVD and PACVD. It has been designed with racing and high performance engine applications in mind. The ACP coating is applied at a temperature range of 180°C – 350 °C.

Due to their unique combination of properties, DLC coatings are extremely effective in many other tribological and wear applications, such as: